- Home Page

- Company Profile

-

Our Products

- Roofing Sheet

- Upvc Roofing Sheet

- Frp Roofing Sheet

- Jsw Galvanized Roofing Sheets

- Galvalume Roofing Sheets

- Colored Roofing Sheet

- Corrugated Steel Sheet

- JSW Profile Roofing Sheets

- Pre-coated Aluminium Roofing Sheets

- Aluminium Roofing Sheets

- Curved Roofing Sheet

- MS Roofing Sheet

- Curved Tile Profile Sheet

- UPVC Roof Sheet

- Tile Profile Sheet

- Color Coated Aluminium Roofing Sheets

- Pre Painted Galvanized Roofing Sheets

- Colored Polycarbonate Sheets

- Trapezoidal Roofing Sheet

- Transparent Polycarbonate Sheet

- FRP Roofing Polycarbonate Sheet

- Bare Aluminium Roofing Sheets

- Polycarbonate Sheets

- Aluminium Roofing Sheet

- Crimping Roofing Sheet

- Hi Rib Profile Sheets

- Curved Sheet

- Fibre Roofing Sheets

- Tile Sheet

- Steel Roofing Sheet

- Pre Coated Aluminium Roofing Sheets

- PVC White Transparent Roofing Sheets

- Galvanised Roofing Sheets

- Pre Coated Roofing Sheets

- Tile Profile Roofing Sheet

- Essar Galvanized Roofing Sheets

- Polycarbonate Roofing Sheets

- Side Cladding Sheets

- Trapezoidal Roofing Sheets

- Crimp Curved Roofing Sheet

- GI Profile Sheet

- Stainless Steel Roofing Sheets

- Pre Painted Roofing Sheets

- Color Coated Roofing Profile Sheets

- Bare Galvalume Roofing Sheets

- Corrugated Roofing Sheets

- Color Coated Galvalume Roofing Sheets

- Metal Roofing Sheets

- Color Coated Galvanized Roofing Sheets

- Colour Coated Tile Profile Sheet

- GI Roofing Sheet

- Pre Painted Galvalume Roofing Sheets

- Insulated Roofing Panels

- Roofing Sheet Replacement

- Decking Sheet

- Pre Engineered Buildings

- Roofing System

- Air Ventilator

- Color Coated Coils

- Grating

- Roofing Screws

- Sandwich Roof Panel

- Purlins

- Polycarbonate Sheet

- Trussless Roof

- Colour Coated Sheets

- Conventional Industrial Shed

- Metal Sheet

- Prefabricated Structure

- Roofing Sheet

- Contact Us

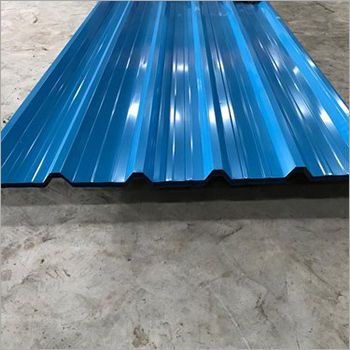

Pre Coated Roofing Sheets

305 INR/Square Meter

Product Details:

- Material Galvanized Sheet

- Type Pre Coated Roofing Sheets

- Size Standard

- Shape Rectangular

- Thickness 0.40 mm Millimeter (mm)

- Click to view more

X

Pre Coated Roofing Sheets Price And Quantity

- 300 Square Meter

- 305 INR/Square Meter

Pre Coated Roofing Sheets Product Specifications

- Pre Coated Roofing Sheets

- Standard

- Rectangular

- 0.40 mm Millimeter (mm)

- Galvanized Sheet

Pre Coated Roofing Sheets Trade Information

- 23000 Square Meter Per Month

- 8-10 Days

Product Description

Available with galvanized coating, offered Pre Coated Roofing Sheets are used as suitable roof sheds in various commercial and residential structures. Made of carbon steel, these sheets are coated with zinc by maintaining standard coating thickness. Quick to install, these roofing materials can resist harsh weather. Thermally insulated Pre Coated Roofing Sheets help to maintain ambient temperature inside buildings by reflecting additional heat associated with their exposure to the UV rays. Long lasing coating thickness, elevated design, anti wear surface, strong corrosion resistance property and standard diameter are the main aspects of these roof construction sheets.

Product details

|

Applicable temperature(degree celsius) |

Less than 450 |

|

Combination |

55% aluminum, 43.5% zinc, 1. 5% silicon |

|

Painting thickness (bottom) |

5-7 microns |

|

Painting thickness (top) |

18-20 microns |

|

Tolerance |

0. 03 mm |

|

Application Areas |

Domestic, Transportation, Agriculture |

|

Surface Treatment |

Color Coated |

|

Thickness Of Sheet |

1mm,2mm,3mm,4mm,5mm |

|

Color |

Available in Black, Blue, Green, Red |

Applications of Pre Coated Roofing Sheet:

1. Residential Roofing: Pre-coated roofing sheets are extensively used in residential construction for roofing purposes. They offer durability, weather resistance, and come in a variety of colors and designs, allowing homeowners to match their roofing to their architectural preferences.

2. Commercial and Industrial Buildings: These sheets are widely used in commercial and industrial buildings such as warehouses, factories, workshops, and retail outlets. They provide excellent protection against harsh weather conditions, UV radiation, and chemical exposure, making them suitable for various industrial environments.

3. Agricultural Buildings: Pre-coated roofing sheets are commonly used in agricultural structures such as barns, poultry sheds, and greenhouses. They provide effective protection against rust, moisture, and heat, ensuring a longer lifespan for the structures.

4. Institutional Buildings: Schools, hospitals, and other institutional buildings often use pre-coated roofing sheets due to their durability, low maintenance requirements, and aesthetic appeal. These sheets can withstand heavy foot traffic and offer insulation properties, helping to maintain comfortable indoor temperatures.

5. Recreational Facilities: Pre-coated roofing sheets are used in recreational facilities like sports complexes, stadiums, and entertainment venues. They offer weather resistance and come in vibrant colors, enhancing the overall aesthetics of the structures.

6. Architectural Projects: Architects often specify pre-coated roofing sheets for various architectural projects due to their versatility in design and color options. These sheets can be shaped into different profiles and installed in creative ways to achieve unique architectural features.

7. Renovation and Retrofitting: Pre-coated roofing sheets are also used in renovation and retrofitting projects to replace old or damaged roofing materials. They provide a cost-effective solution for upgrading existing structures while improving their aesthetics and performance.

8. Transportation Infrastructure: Pre-coated roofing sheets are utilized in transportation infrastructure projects such as bus shelters, railway stations, and airport terminals. They offer protection against weather elements and come in lightweight options, reducing the overall load on the structures.

9. Modular Construction: With the rise of modular construction techniques, pre-coated roofing sheets are increasingly being used in prefabricated buildings and modular housing units. They offer quick installation, durability, and customization options, making them ideal for off-site construction projects.

Pre Coated Roofing Sheet FAQ:

Q. What are pre-coated roofing sheets?

Ans: Pre-coated roofing sheets, also known as pre-painted or color-coated roofing sheets, are metal sheets that come with a layer of paint or polymer coating applied on both sides. This coating provides protection against corrosion, weathering, and enhances the aesthetic appeal of the roofing material.

Q. What materials are pre-coated roofing sheets made of?

Ans: Pre-coated roofing sheets are typically made of materials such as galvanized steel, galvalume (a combination of galvanized steel and aluminum), or aluminum. These materials offer durability and corrosion resistance, making them suitable for roofing applications.

Q. What are the advantages of using pre-coated roofing sheets?

Ans: Below are some of it's advantages:

1. Resistance to corrosion and weathering

2. Aesthetic appeal with a variety of color options

3. Durability and long lifespan

4. Low maintenance requirements

5. Lightweight and easy to install

6. Good thermal insulation properties

Q. Are pre-coated roofing sheets suitable for all weather conditions?

Ans: Yes, pre-coated roofing sheets are designed to withstand various weather conditions including rain, snow, hail, and UV radiation. The coating provides protection against corrosion and fading, ensuring longevity even in harsh climates.

Q. Can pre-coated roofing sheets be customized?

Ans: Yes, pre-coated roofing sheets can be customized in terms of color, design, and profile to meet specific architectural and aesthetic requirements. Manufacturers offer a wide range of options to choose from, allowing customers to select the most suitable roofing solution for their projects.

Q. How are pre-coated roofing sheets installed?

Ans: Pre-coated roofing sheets are typically installed using screws or nails, which are fastened to the underlying structure such as roof trusses or purlins. Proper installation techniques and accessories such as ridge caps, flashing, and sealants are used to ensure watertightness and durability.

Q. Are pre-coated roofing sheets environmentally friendly?

Ans: Pre-coated roofing sheets are considered environmentally friendly as they are recyclable and contribute to energy efficiency when used in combination with insulation materials. Additionally, the durability and long lifespan of these sheets reduce the need for frequent replacements, further minimizing environmental impact.

Q. How do I maintain pre-coated roofing sheets?

Ans: Maintenance of pre-coated roofing sheets typically involves periodic cleaning to remove dirt, debris, and organic growth such as algae or moss. Mild detergent and water can be used for cleaning, avoiding harsh chemicals or abrasive materials that may damage the coating.

Q. What is the expected lifespan of pre-coated roofing sheets?

Ans: The lifespan of pre-coated roofing sheets depends on factors such as the quality of materials, installation techniques, and environmental conditions. However, with proper maintenance, pre-coated roofing sheets can last for 20 to 30 years or more.

Q. Are pre-coated roofing sheets fire-resistant?

Ans: Pre-coated roofing sheets can be made fire-resistant by using coatings or additives that enhance their fire-retardant properties. It's important to check with the manufacturer or supplier for specific fire-resistance ratings and certifications when selecting roofing materials for fire-prone areas.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Roofing Sheet' category

"We are accepting bulk order quantity from Gujarat, Maharashtra, Rajasthan and Madhya Pradesh."

Call Me Free

Call Me Free